PDEng DCW 11: a week full of challenges

Posted on

Seven days, 31 participants from 14 different countries with different cultures and different time zones. Sounds challenging? It isn’t called the Data Challenge Week for nothing!

The Data Challenge Week (DCW), the selection week for PDEng Data Science Trainees, is usually a pressure cooker week full of hard work, intensive projects and new friendships. During this week, participants work and live together 24/7. How do you move an event like this online when it’s impossible to meet each other in person due to a global pandemic? The organization team worked hard to provide a great experience for the participants. We talked to a group of participants to find out if they succeeded.

Focus on the design process

“On Friday, we started the DCW with the kick-off meeting. We used introduction games to get to know each other better,” says participant Anela Asabella. “From Saturday, we dived into the challenge. Our main focus was the design process. We started without data: understanding the problem, defining our goals, and brainstorming ideas to solve the problem. During the brainstorm session, more than 50 ideas were generated by each group.” Xiaoheng Huang, another participant, adds: “After the brainstorm, everyone was exited to finally dive into the data. After cleaning the data, we performed an Exploratory Data Analysis to find trends and patterns in the data. Finally, we worked on models and visualization to present our solutions for each challenge.”

Digital innovations for social interactions

The social part, which makes this week so special, wasn’t overlooked this time. Trainees Ambika, Lei and Razieh came up with some innovative online ideas for the social event on Sunday. “We started the event with the wheel of questions. No one could escape! We were asked some tough question, like what was your most embarrassing moment in high school or what was the last lie you have told,” says Iris Bokkes. ” Afterwards, we played a game of storytelling, followed by a personal bingo game and ended the afternoon playing the DCW game Pictionary. This last game was not only played on Sunday, but was also often used as a break from our hard work during the week.”

Real companies, real challenges

The challenges from the DCW were delivered by four different companies (see below). This gave participants the opportunity to work on real problems, with real data, and come up with realistic solutions. Participant Akshaya Ravi: “Though the challenges were different, we all shared one goal: improve production processes.”

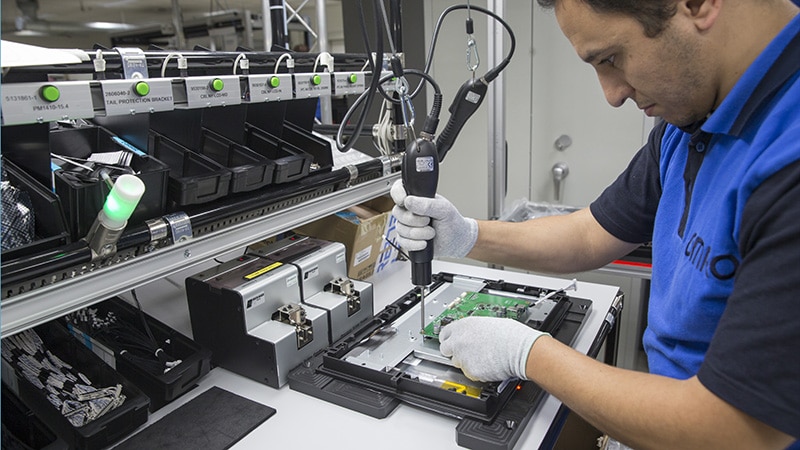

Omron: Towards data driven analysis and predictive modelling of a NA5 production line.

Omron’s challenge is based on the manufacturing process of an HMI product called NA5 from Omron Manufacturing at ‘s-Hertogenbosch. Currently, the quality issues are analyzed after they have occurred at respective stages of the assembly process. This leads to delay in the assembly process, difficulty in root cause analysis, and scrapping of the material, if the issue is not resolved. In order to address these challenges, Omron would like to predict the quality of the product before any issue has occurred in the manufacturing process. A group of eight people supported this goal with data driven solutions.

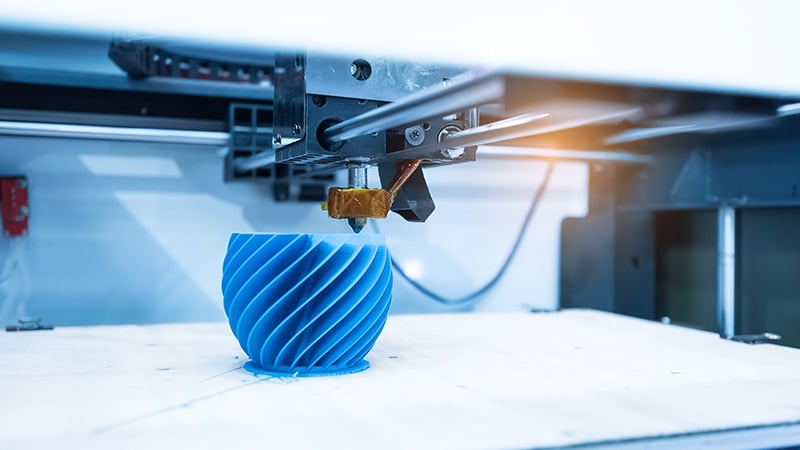

Additive Industries: Design a data-driven method for recoater jam pattern recognition

Design a data-driven method for recoater jam pattern recognition was the challenge from Additive Industries. This challenge aims at analyzing the problem of one component of a 3D printing machine: the recoater. The problem comes from the protrusion of some layers which blocks the movement of recoater. If this problem occurs, the whole machine stops working. A team of seven people worked on this challenge during DCW11.

VTEC: Improve accuracy of people count by combining IR camera and sensor data

Third challenge from VTEC is related to people count in smart buildings. How can we improve the accuracy of people count by taking into consideration more sensor data such as RTVOC, CO2, temperature. The current accuracy, as measured by an IR camera is 85%, and the company wants to improve it as much as possible. It has been observed that there is a high correlation between other sensors and the number of people inside a room.

Damen Shipyards: Minimizing ship vibrations by optimization and detection of propeller position.

Damen Shipyards is a company specializing in ship design, ship building and ship repair. In one type of cargo ship they experienced heavy vibrations. Imbalanced propellers produced vibrations at the same frequency as the natural frequency of the frame of the ship, which caused the entire ship to vibrate. These vibrations cause discomfort for the crew and damage to the ship. Damen built a test setup representing the propulsion system of the ship to investigate this problem. During this data challenge week, a team of 8 used the data from this test setup to take a first step solving this problem. The team investigated the position of the propellers that minimizes the vibrations. In addition, the team worked on a model to predict the current position of the imbalanced propellers.

Immersion from ideation to prototype

During the week , the teams worked really hard and had fun together. Wednesday morning, everyone started to feel excited and worked hard to get their presentations ready. The presentations were a success, and each team showed some very interesting insights.”

“The Data Challenge Week has been one of the quickest holistic immersion in a data science project from ideation to prototype. In a span of 6 days, our team came up with a prototype that was able to establish a machine learning approach that could aid the production process at the stakeholder’s site, ” concludes participant Vibhor Sharma, one of the participants.

More information

To learn more about the PDEng in Data Science, visit the PDEng in Data Science page.

To learn more about business opportunities, for example to deliver a project for PDEng trainees, visit the PDEng for business page.